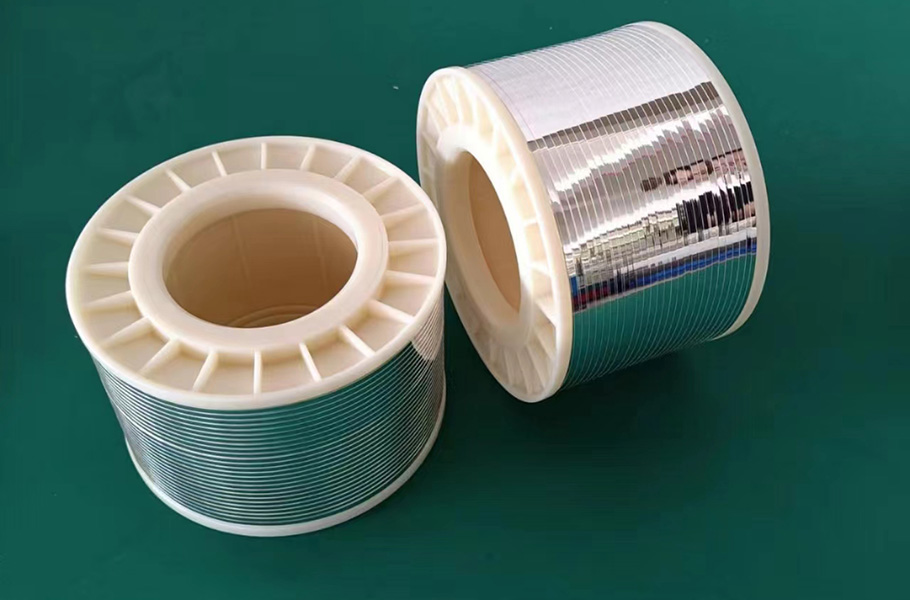

Silver plated copper tape

| Mechanical properties of soft silvered copper wire | ||||||

| Serial number | Specifications(mm) | Width tolerance(mm) | Thickness tolerance(mm) | Elongation(%) | Tensile strength(Mpa) | Dc resistivity |

| 1 | 1.5X0.05 | ±0.03 | ±0.003 | ≥20 | ≥196 | ≤0.01820 |

| 2 | 1.2X0.05 | ±0.03 | ±0.003 | ≥20 | ≥196 | ≤0.01820 |

| 3 | 2.4X0.05 | ±0.03 | ±0.003 | ≥20 | ≥196 | ≤0.01820 |

| Detection mode | ||

| Serial number | Item | Test mode |

| 1 | Silver layer and content | Coating thickness gauge |

| 2 | Standard width and thickness dimensions and deviations | Myriameter |

| 3 | Electrical resistivity | GB/T3048.2-2007 |

| 4 | Mechanical property | Tensile and elongation testing machine |

| 5 | Appearance | Eye, magnifying glass |

| 6 | Coating continuity | GB/4909.9-2009 |

| Enforce standards | Q/ SY06-2018, refer to JB/ T3135-2011, ASTM B 298-99 |

| Type number | HBY |

| Technical parameter | The surface of the silver-plated copper wire should be smooth and not discolored, without metal particles, burrs, any mechanical damage and other defects that damage the quality of the product. The coating is continuously and firmly attached to the surface of the copper wire, and there is no spot, black and discoloration phenomenon within 30 minutes at + (400±5) ℃ |

| According to customer requirements, the silver layer thickness of more than 1 micron silver plated copper wire should be subjected to sodium polysulfide test 1-3 cycles, no black |

Previous post:No more

Next chapter:No more