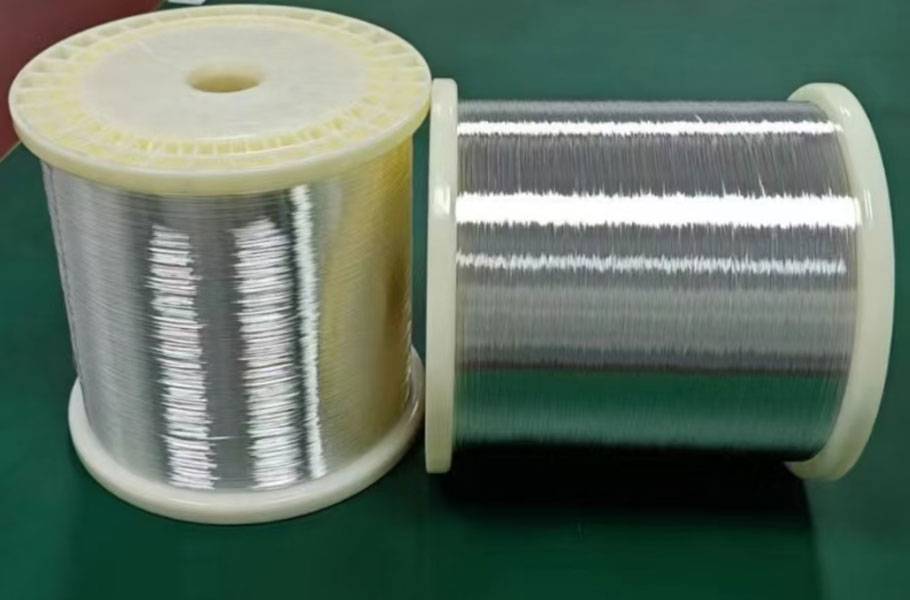

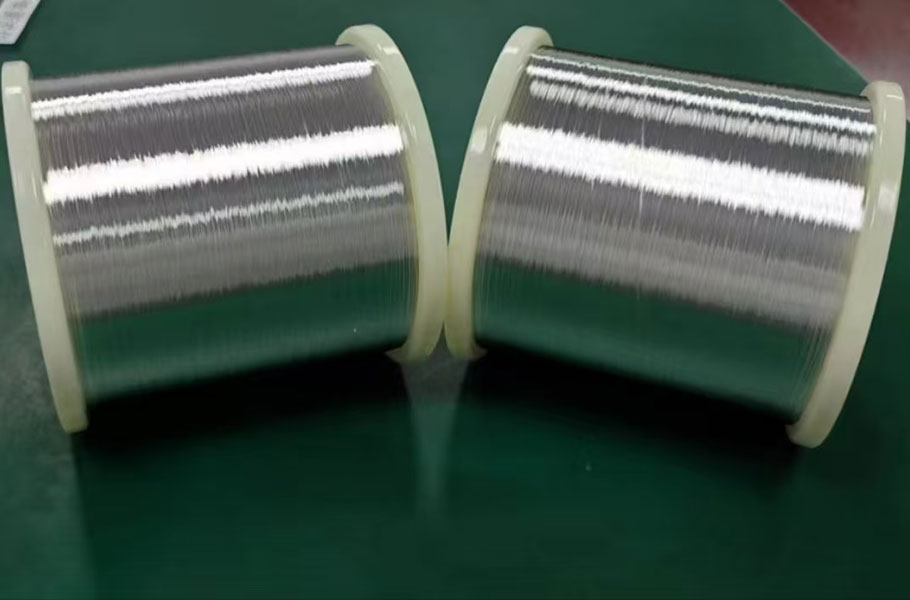

Silver plated copper clad steel

| Specifications and technical parameters | |||||

| Size mm | Silver content % | Wire diameter tolerance mm | Elongation at break is greater than % | Tensile strength | Dc resistance +20℃ |

| Not less than n/mm2 | Not greater than Ω/m | ||||

| 0.92 | 1.25 | ±0.015 | 10 | 352 | 0.066 |

| 0.93 | 1.25 | ±0.015 | 10 | 352 | 0.065 |

| 0.94 | 1.25 | ±0.015 | 10 | 352 | 0.063 |

| 0.8 | 1.25 | ±0.01 | 10 | 352 | 0.087 |

| 0.51 | 2 | ±0.01 | 10 | 352 | 0.215 |

| 0.29 | 0.5 | ±0.01 | 10 | 352 | 0.66 |

| 0.2 | 3.5 | ±0.05 | 10 | 352 | 1.4 |

| 0.1 | 6.1 | ±0.03 | 10 | 352 | 5.6 |

| 0.17 | 4 | ±0.05 | 10 | 352 | 1.9 |

| Enforce standards | Q/SY05—2018 |

| Type number | TS Scope of application: This product can be widely used as computer internal connection wire, electronic power industry conductor, communication industry wire and aerospace, military products and other high temperature resistance wire |

| Technical parameter | The base material is copper-covered steel wire, the thickness of the copper layer should not be less than 10% of the radius of the steel wire, and the product quality and characteristics meet the requirements of ASTM B452 40A class (that is, 40% nominal conductivity, soft state, resistivity ≤0.04397Ωmm2/m). |

| The copper clad steel core adopts 40A series annealed flexible wire core, and the thickness of the silver plating layer can be customized according to user requirements. When the thickness of the coating is less than 1.2μm, the continuity and density of the coating are not measured by sodium polysulfide |

Previous post:No more

Next chapter:No more