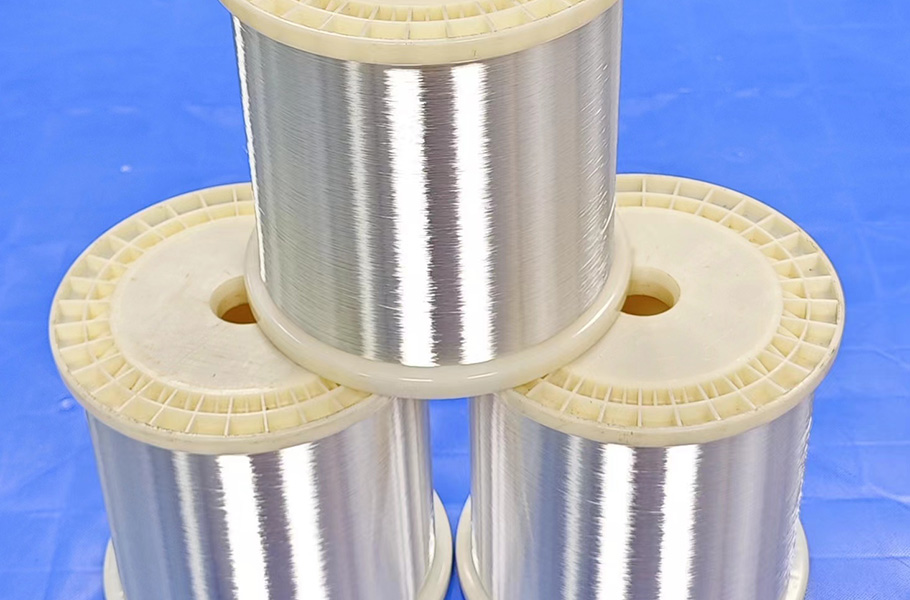

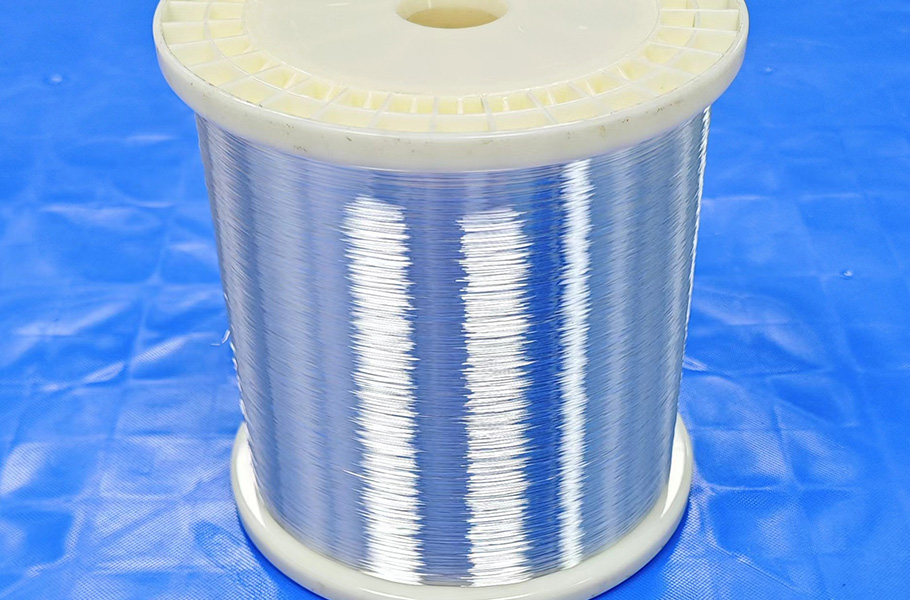

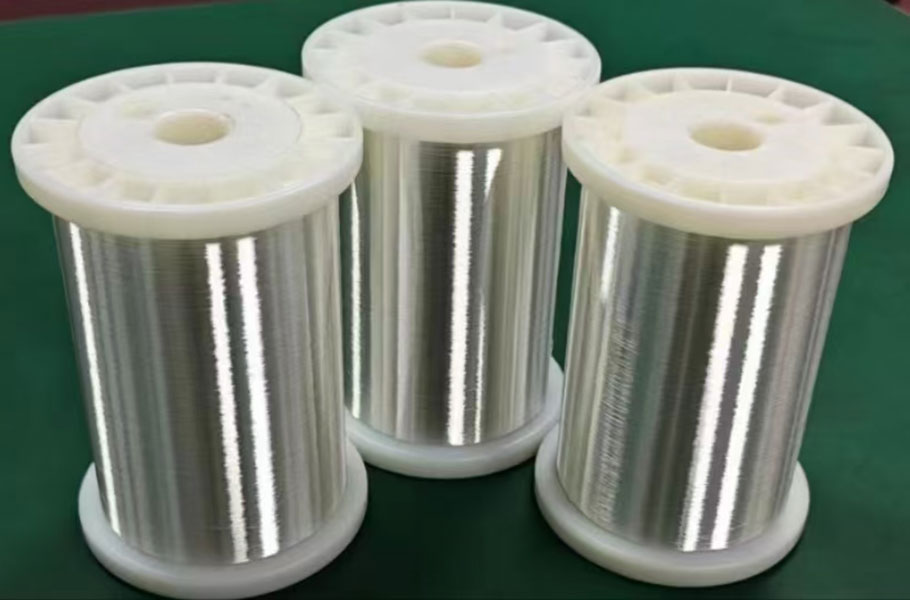

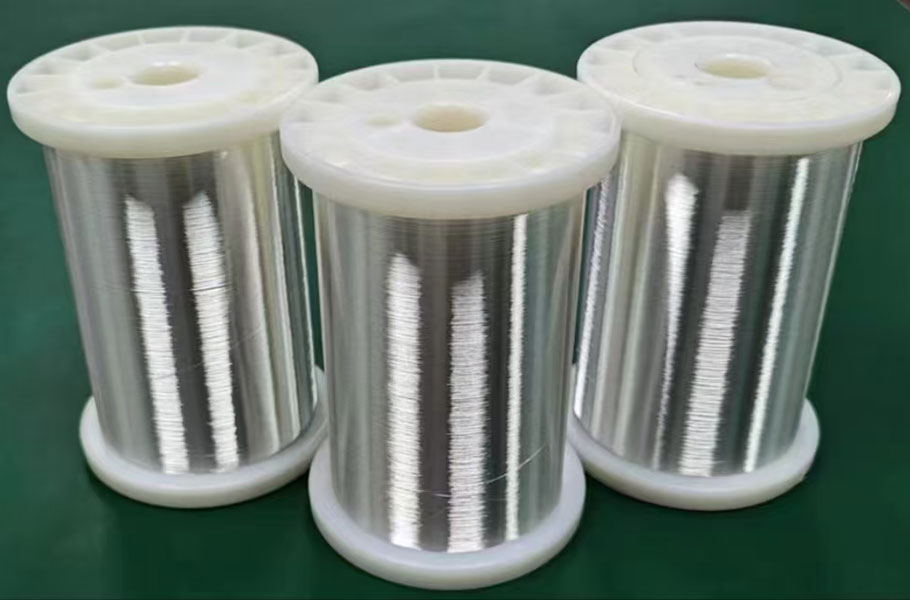

Silver-plated copper

| Mechanical properties of soft silvered copper wire | ||

| Note: The tensile strength of hard silver plated copper wire is not less than 275 N/ mm² | ||

| Nominal diameter mm | The tensile strength is not less than N/ mm2 | Elongation is not less than % |

| 0.05-0.1 | --- | 5.5 |

| 0.11-0.15 | 196 | 10 |

| 0.16-0.25 | 196 | 15 |

| 0.26-0.5 | 196 | 20 |

| 0.51-1.0 | 196 | 25 |

| 1.1-2.0 | 196 | 25 |

| Enforce standards | Q/ SY02-2018, refer to JB/ T3135-1999, ASTM B 298-99 |

| Type number | TRY |

| Scope of application | This product is an excellent conductor of signal transmission, can be widely used as communication cable connection line, electronic power industry conductor, communication industry wire and aerospace, military products and other high temperature resistance wire. Long-term use, the temperature is below +200℃ |

| Technical parameter | When the temperature of silver-plated copper wire is +20℃, the resistivity is less than 0.017241ωmm2 /m, and the temperature coefficient of resistance is 0.003931/℃ |

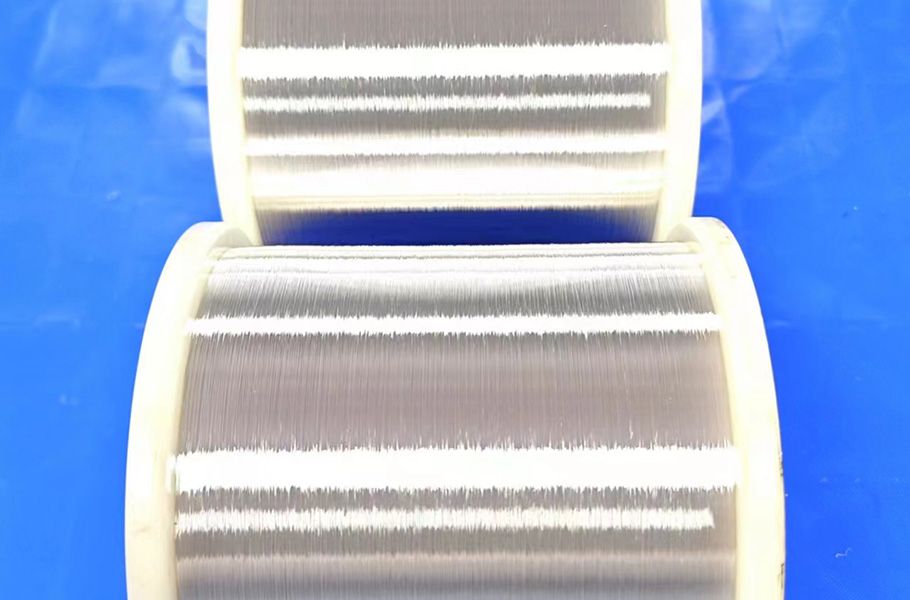

| The surface of the silver-plated copper wire should be smooth and not discolored, without metal particles, burrs, any mechanical damage and other defects that damage the quality of the product. The coating is continuously and firmly attached to the surface of the copper wire, and there is no spot, black and discoloration phenomenon within 30 minutes at + (400±5) ℃. At a visual distance of 25.4cm, no scratches, pits and bumps can be seen on the surface of the product under a 5x microscope. Under a 10x microscope, there should be less than 3 scratches, pits and raised surface defects per 1000mm length of the product surface, and each scratch length should not exceed 3mm, pits should not exceed 0.08 square mm, scratches and pits depth should not exceed 0.005mm, surface bumps should not exceed 0.08 square mm, and height should not exceed 0.005mm | |

| According to customer requirements, the silver layer thickness of more than 1 micron silver plated copper wire should be subjected to sodium polysulfide test 1-3 cycles, no black | |

| Nominal diameter mm | Deviation |

| 0.050-0.100 | ±0.002 |

| 0.110-0.250 | ±0.003 |

| 0.260-0.700 | ±0.005 |

| 0.710-1.000 | ±0.01 |

| 1.100-2.000 | ±0.01 |

Previous post:No more

Next chapter:No more